Customer oriented, Innovative, Efficient

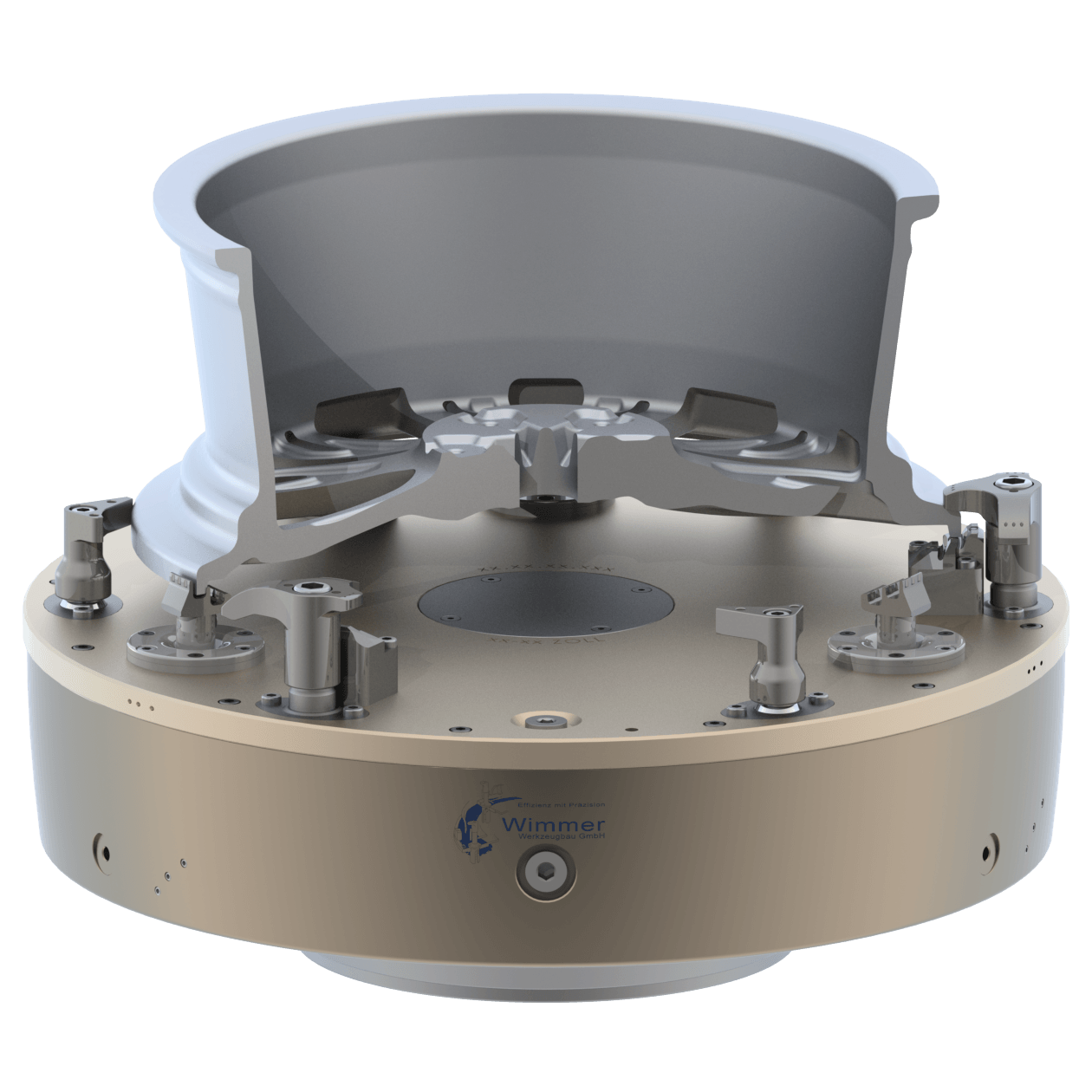

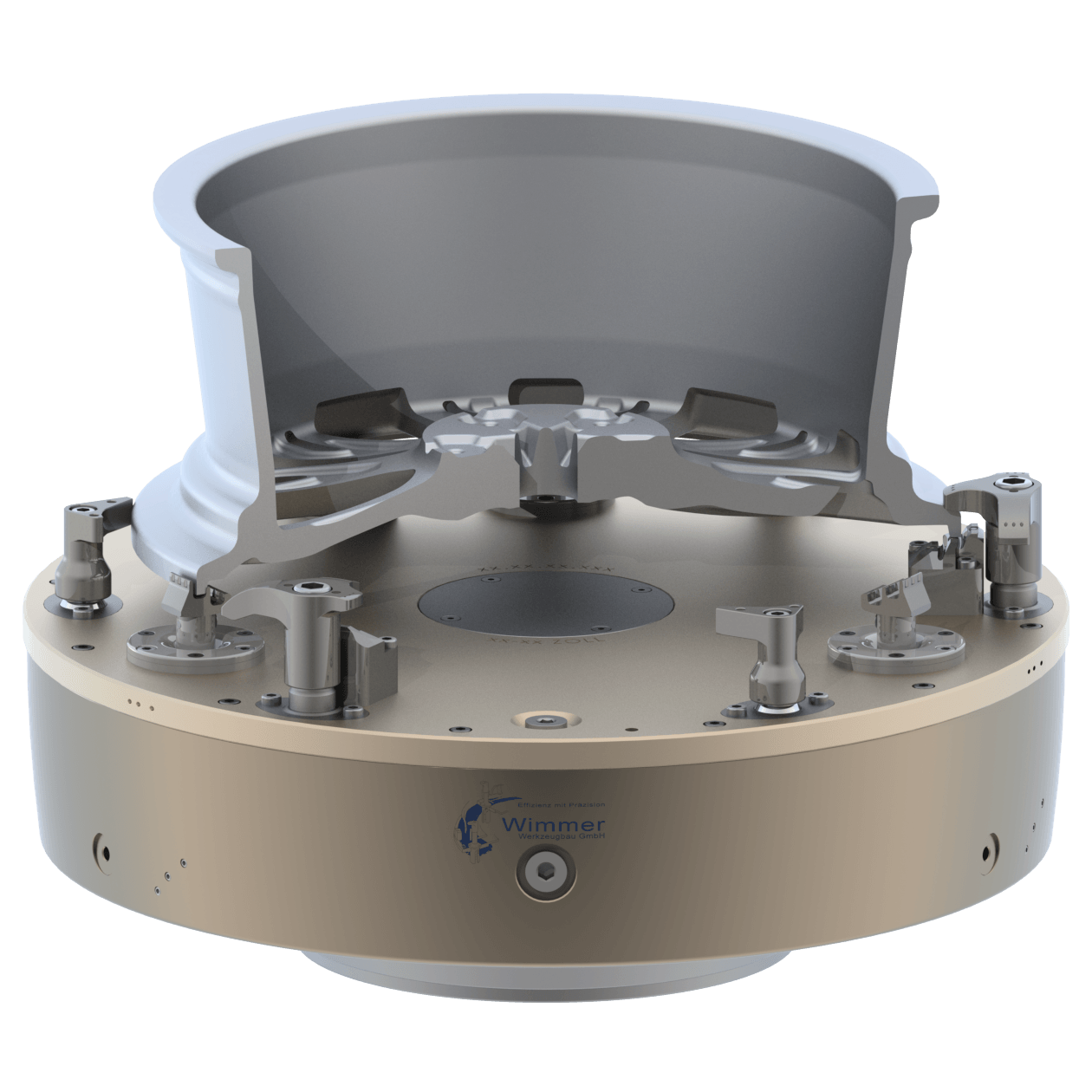

For more than 30 years, Wimmer Werkzeugbau has been a byword for innovative design, modern manufacturing and high quality. Our clients worldwide reward us with orders that require us to continuously expand our premises, machines and works. Today, Wimmer Werkzeugbau GmbH is the global leading manufacturer of clamping devices for flexible rim machining and impresses with a reputation for cutting edge, efficient solutions with the highest quality and reliability.