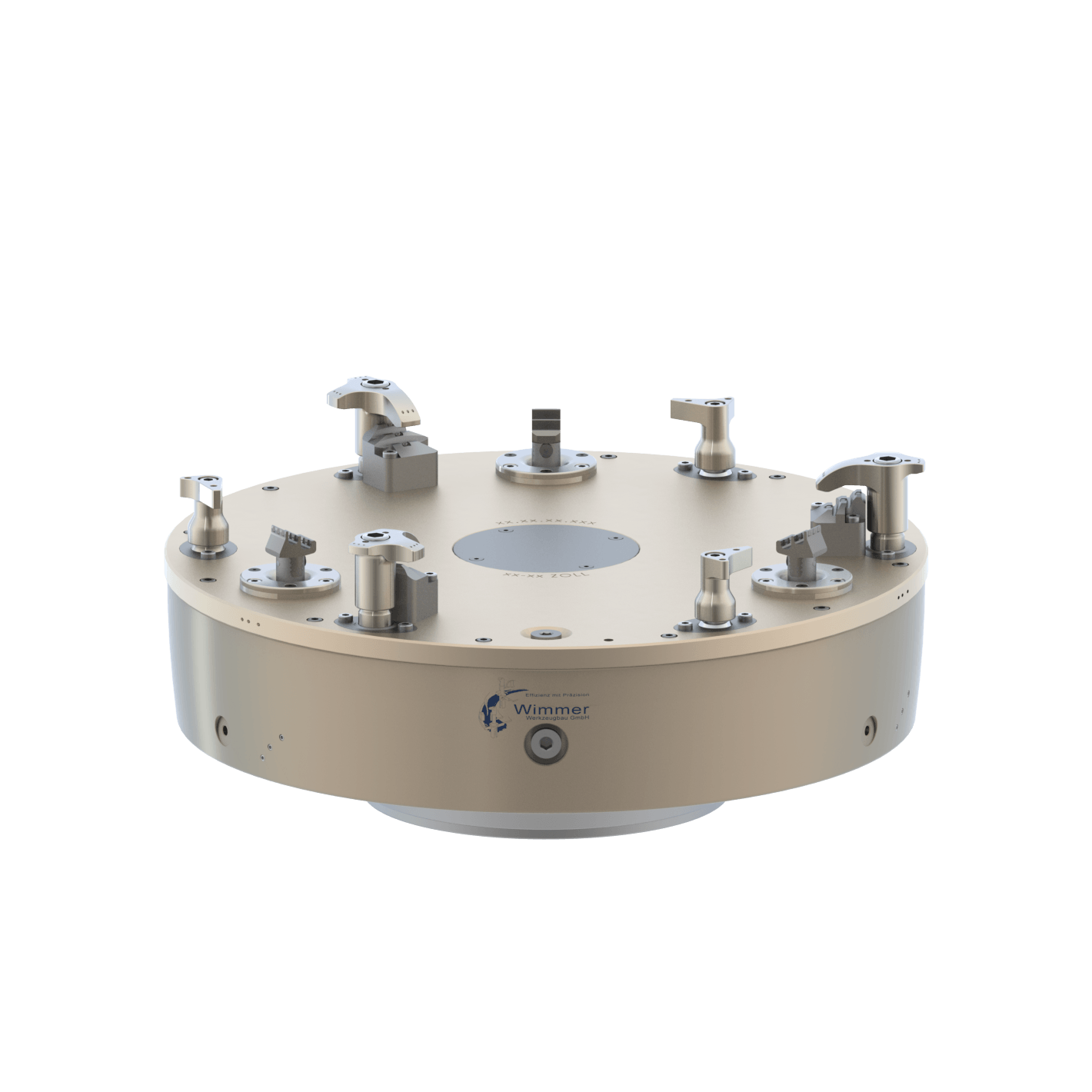

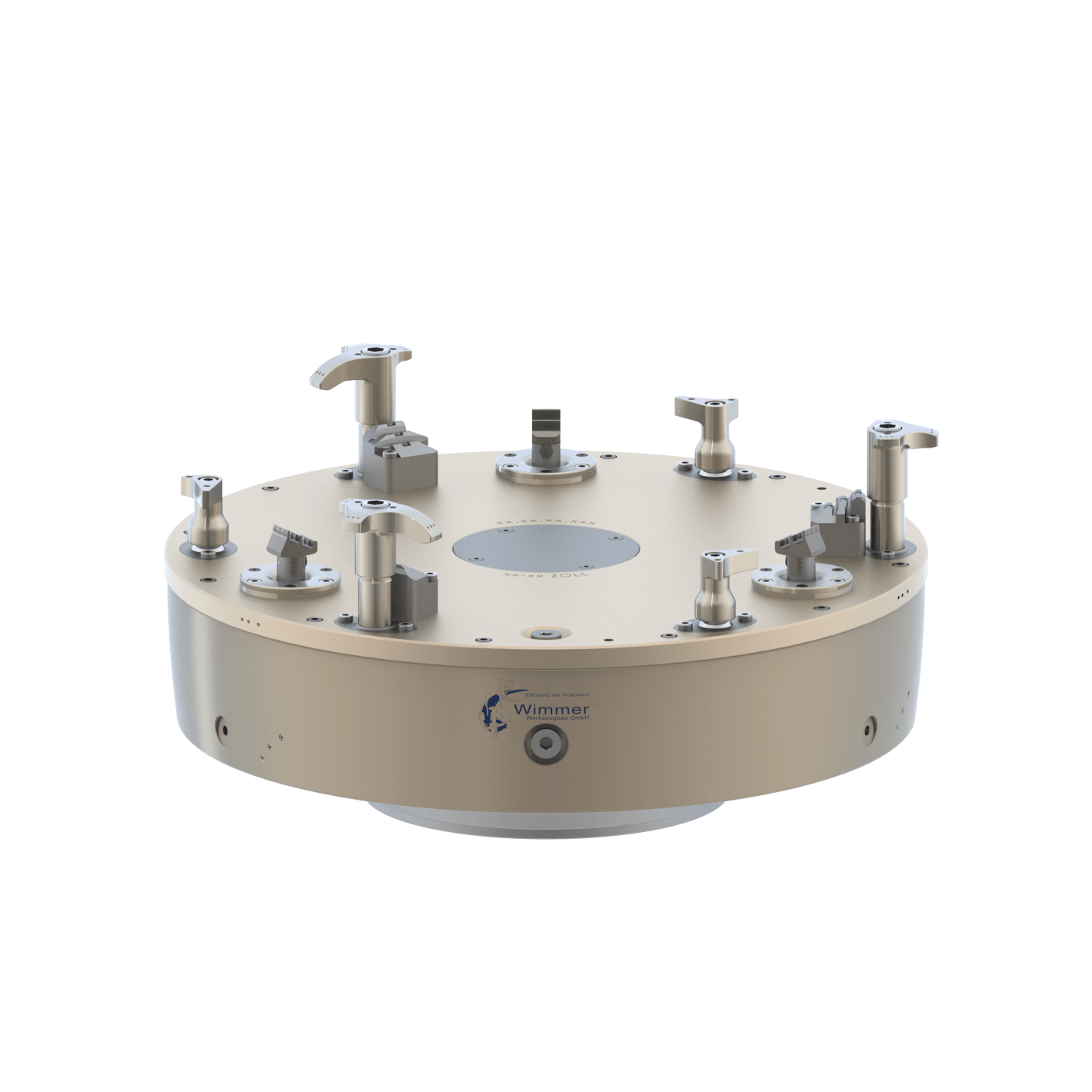

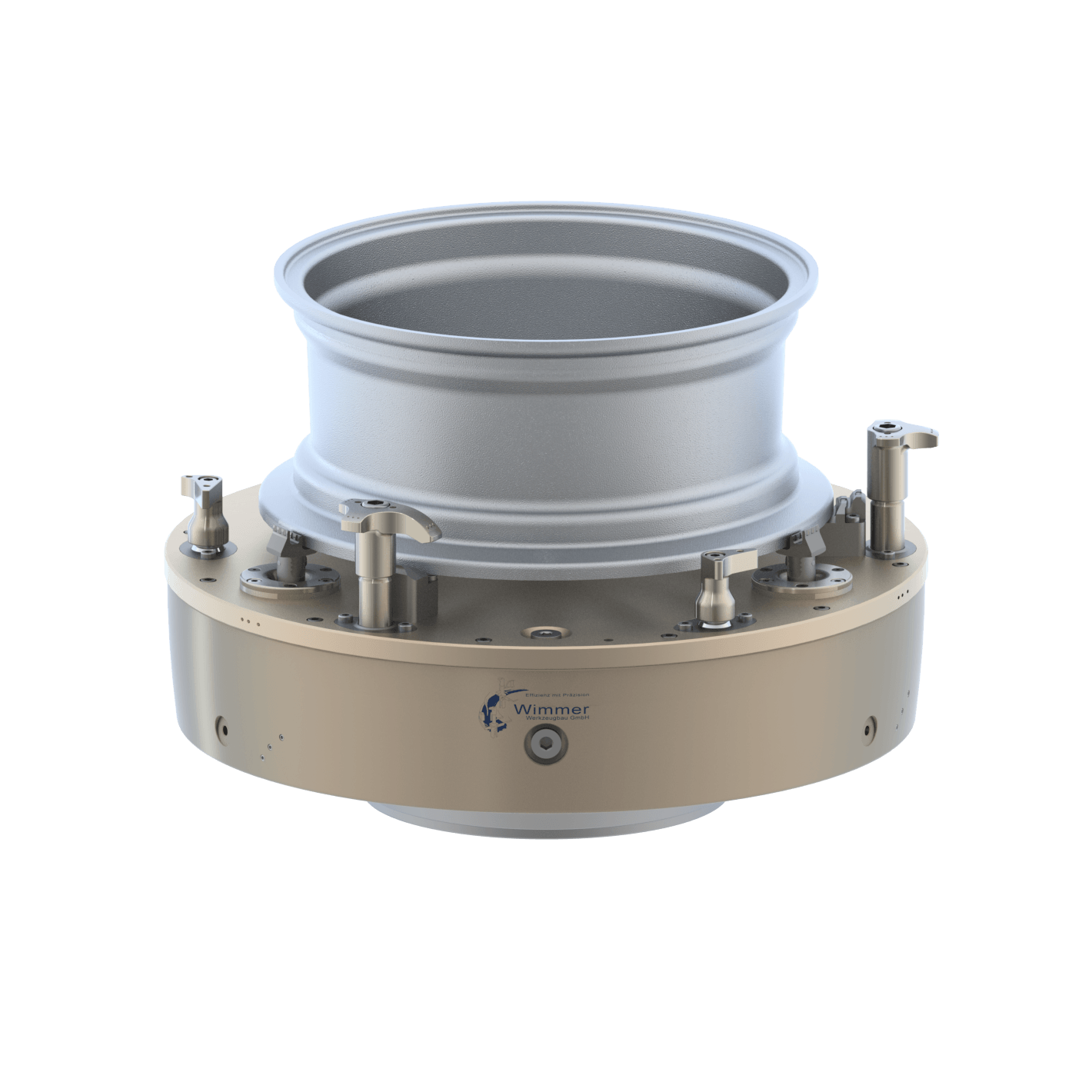

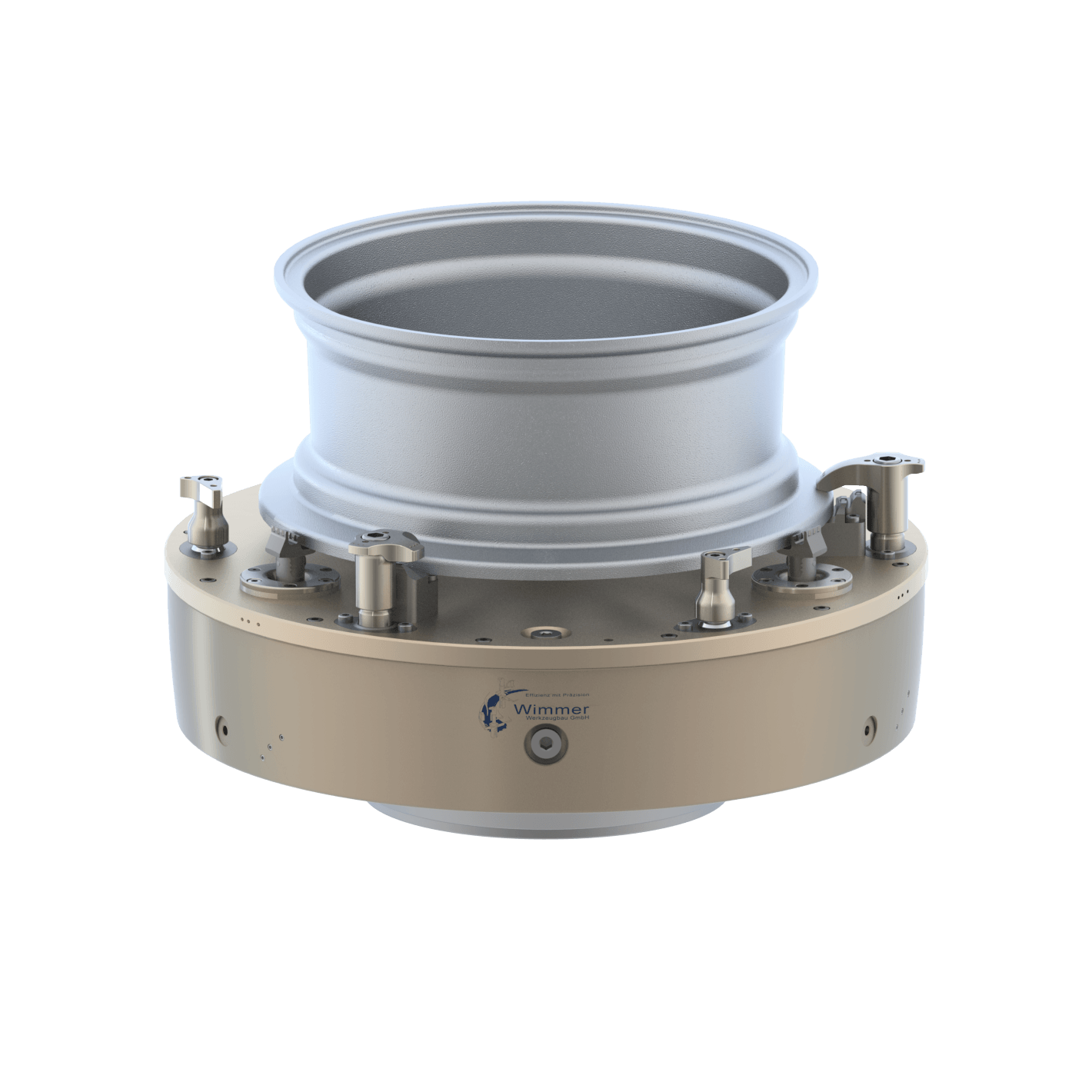

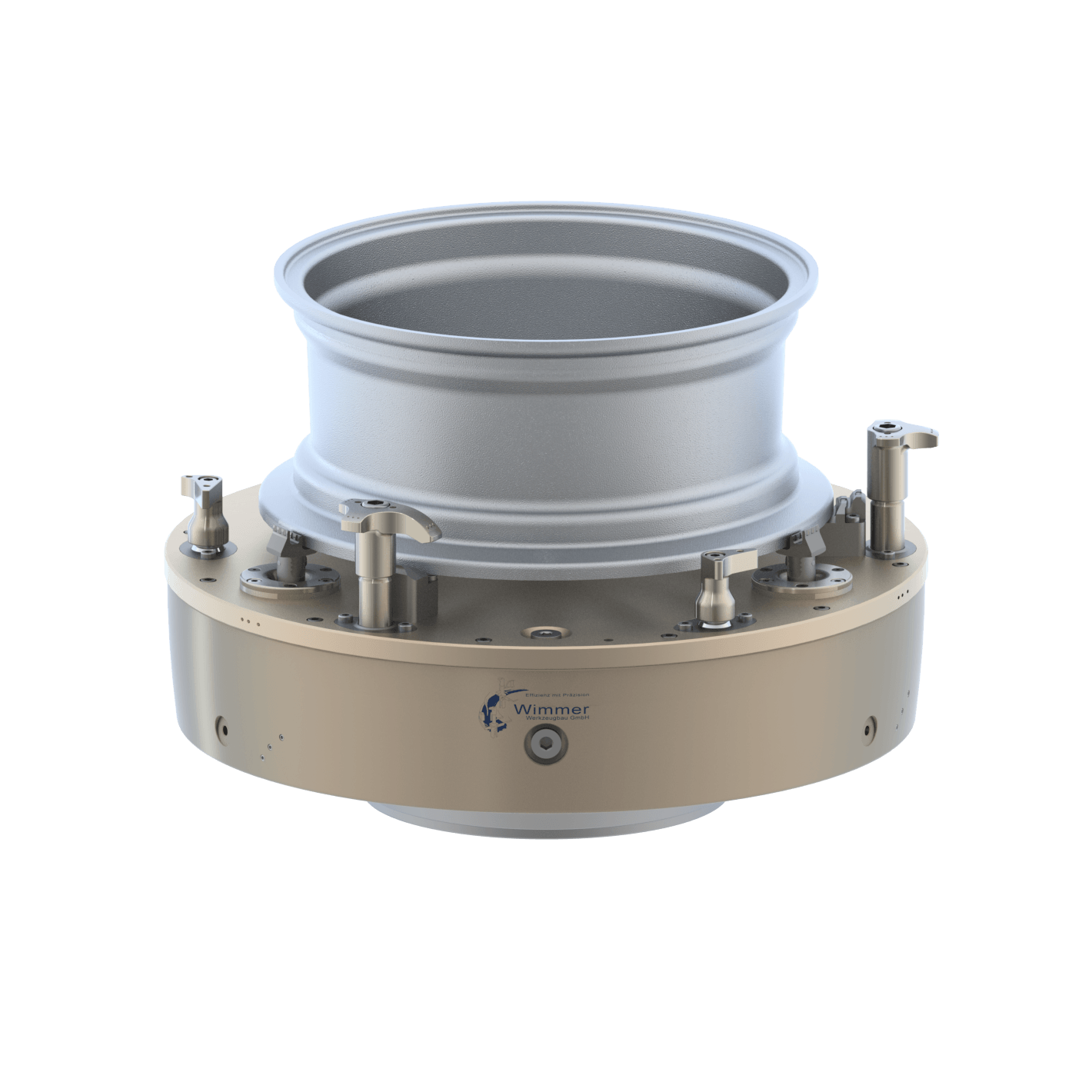

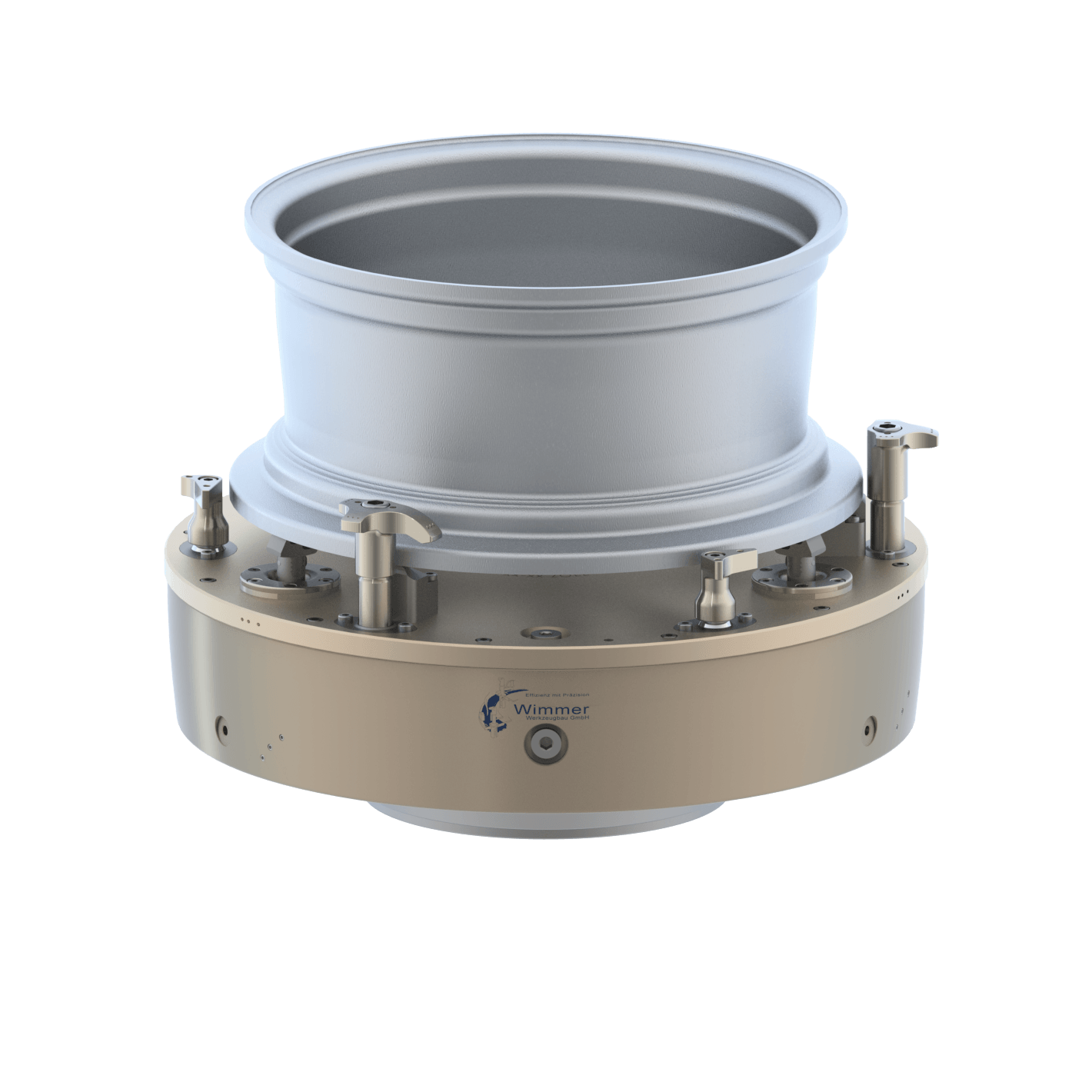

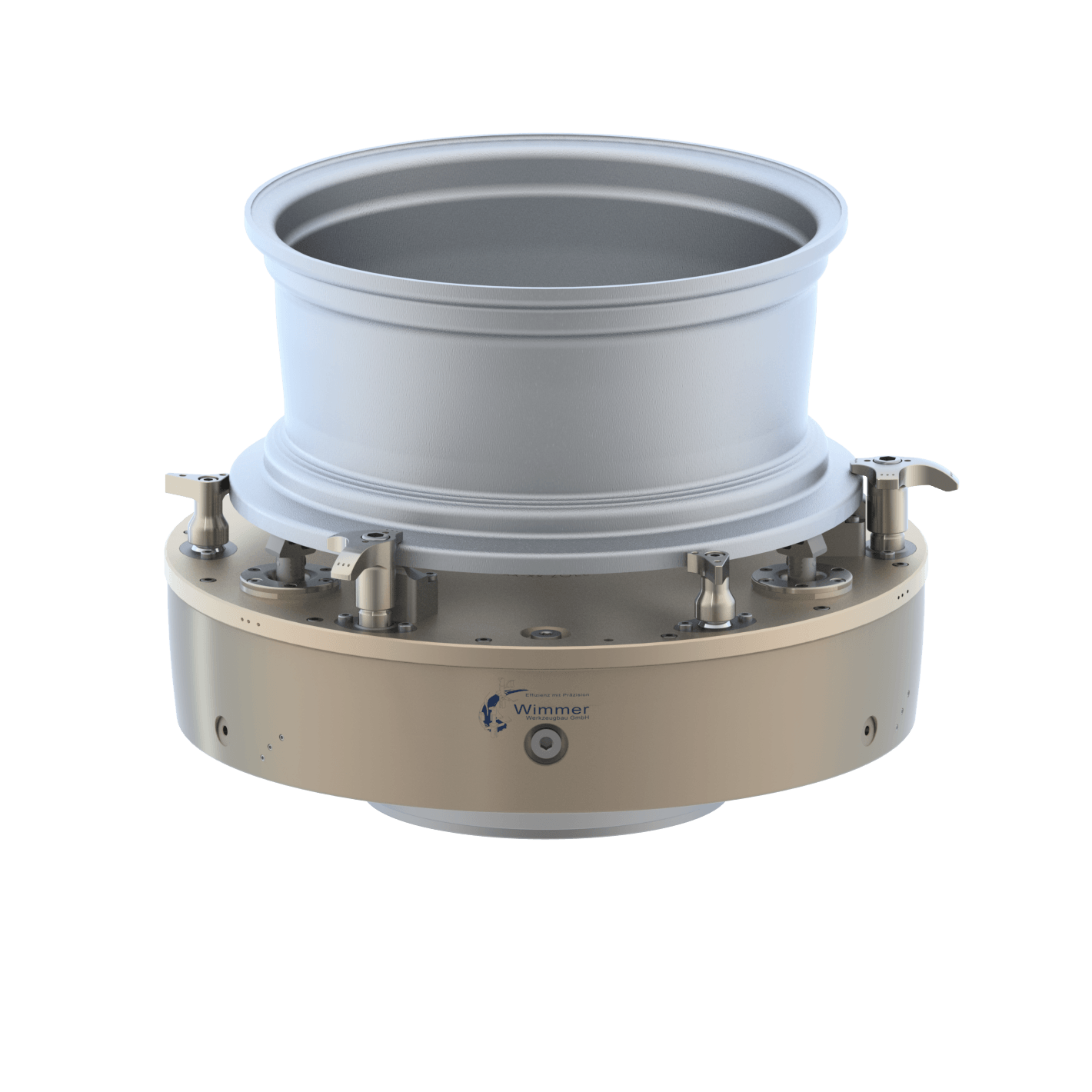

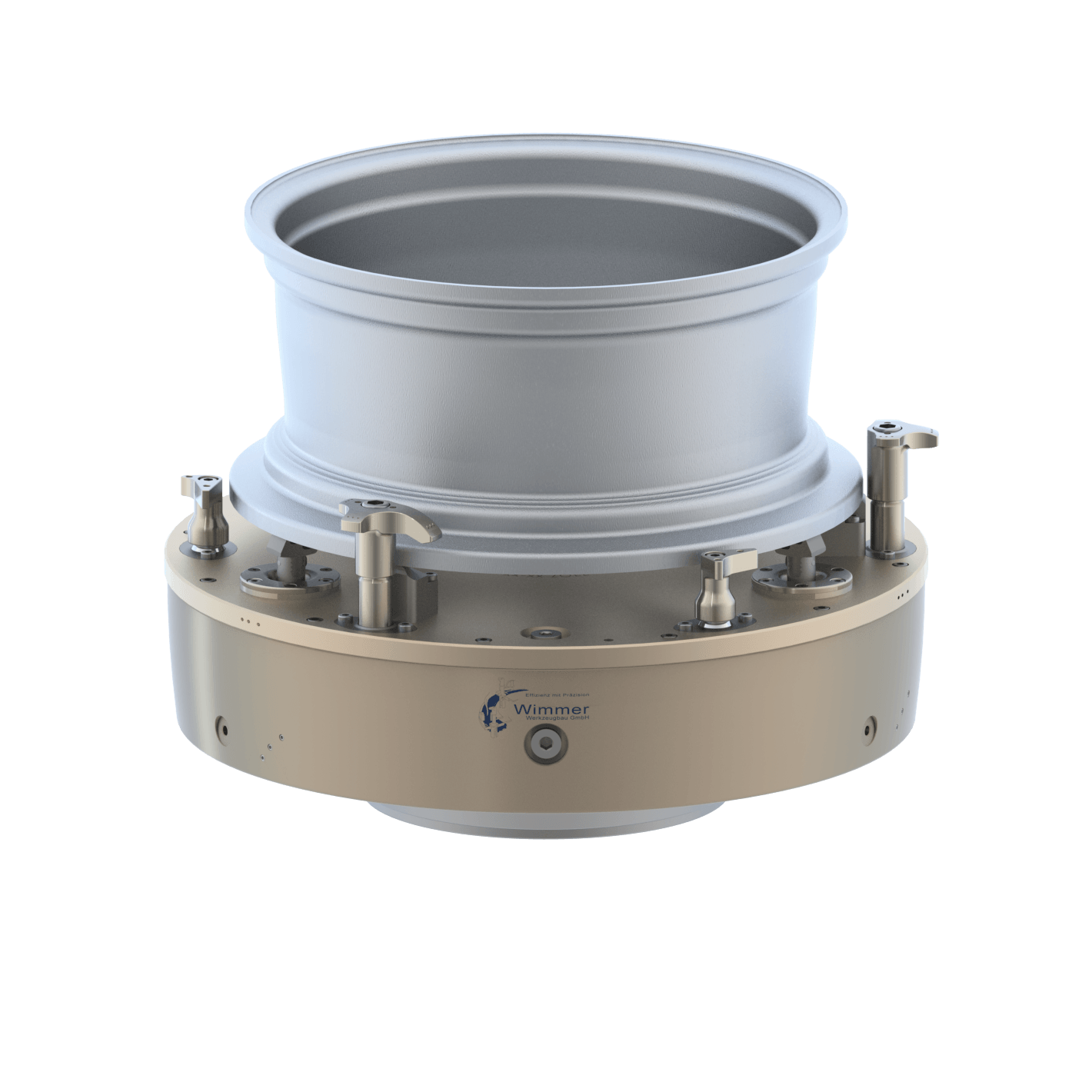

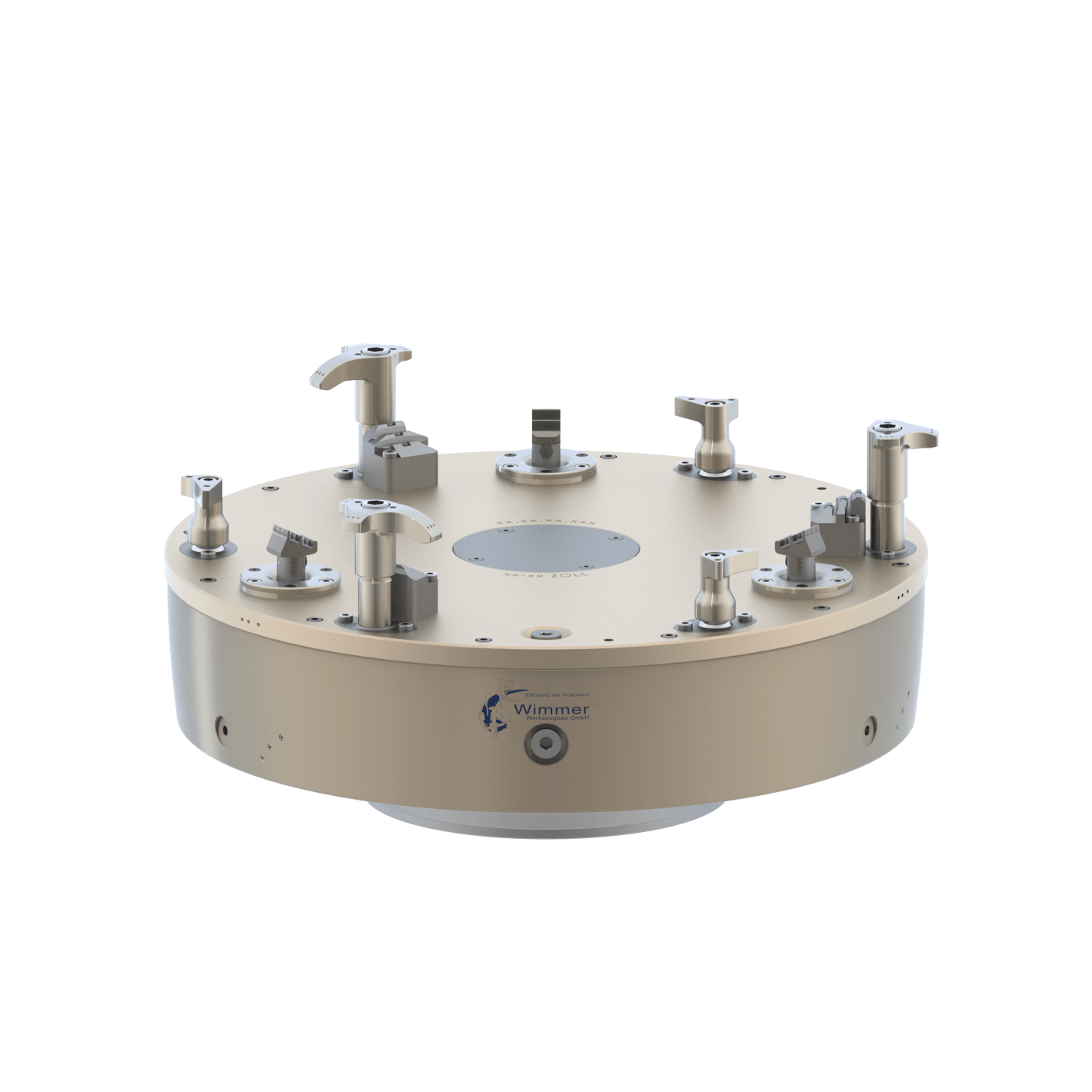

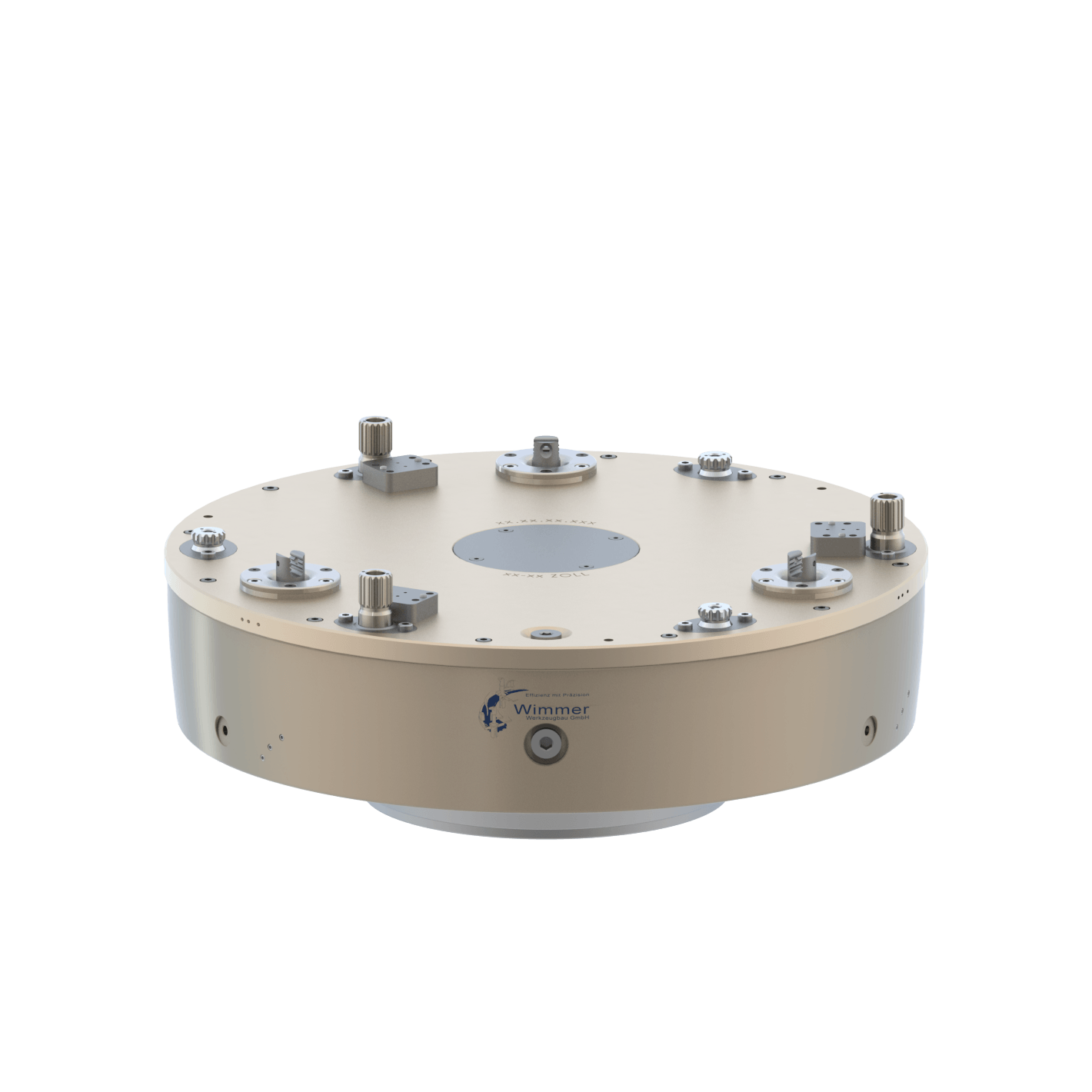

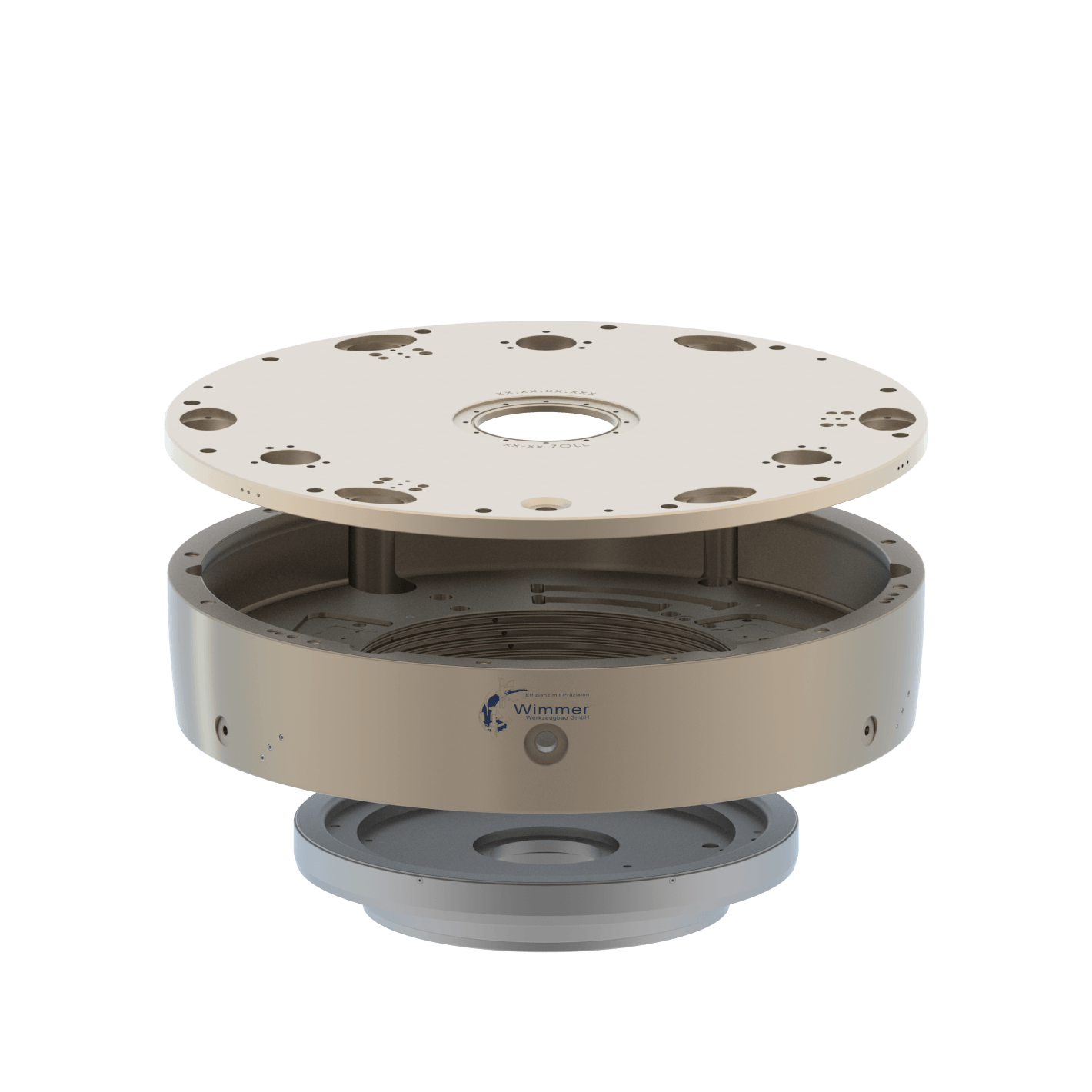

OP1 / OP2

Goal

Our goal was to develop a clamping device which could clamp several rim sizes without retooling. The development of a centrifugal force-neutral system for centring the wheels followed. This allowed us to meet the high demands of concentricity with repeat accuracy.

Cutting-edge light metal alloys are used to reduce weight and shorten the machines’ process times (acceleration and deceleration of the drive spindle).

The main criterion is that no machine retooling is necessary for operation and that the position of the wheel clamped / not clamped can be monitored pneumatically with the machine via the clamping chuck.

The clamping chucks are modular, which allows us high flexibility and allows us to repair single modules if damaged. This saves costs and time.